Temperature Compensator Adjustment:

This article, written by Steve Sutton, first appeared on the Vintage Triumph Register (American) website.

I had problems with my Stag refusing to start when hot. Carrying out this procedure cured it permanently.

The photos are of a spare one I have.

What exactly are Temperature Compensators?

To paraphrase the Haynes 'Zenith-Stromberg CD Carburettor' owners workshop manual:

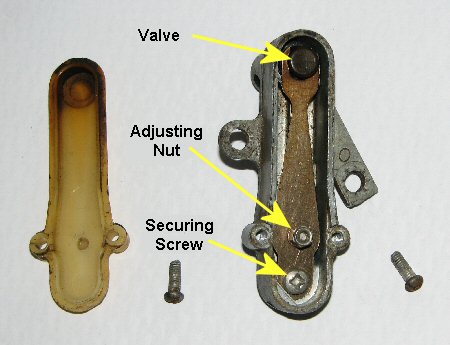

"The temperature compensator (TC) is a rectangular housing with a plastic cover that contains a bi-metallic strip, one end is secured to the housing with a screw or rivet, and an adjusting nut is located part-way along its length. The other end of the strip engages a plastic plunger with a conical end which slides in a cylindrical extension of the housing and thus forms a regulating valve.

Changes in temperature causes the bi-metallic strip to flex, moving the plunger in its bore, regulating the annular area around the bore thus controlling the amount of by-pass air that is allowed into the carburettors mixing chamber."

A common problem with the TC's is that the plastic cylindrical plunger becomes stuck, either open or closed due to buildup of gunk. When this happens the owner usually pulls the TC's apart, removes the bi-metallic strip, cleans off the gunk and puts it back together again. However in doing so, you must remove the adjusting nut, and unless you knew that the middle nut was an adjustment.....you were doomed.

The specifications on how to adjust the TC's were a closely guarded secret at the Zenith Carburettor factory and were never revealed to any known, living person!

The following is the procedure I used on my 1974 1/2 model TR-6, fitted with Zenith-Stromberg 175CD-SEVX carburettors. I imagine the procedure to be identical for any ZS carburettor fitted with TC's.

First remove the bi-metallic strips. At room temperature they should be straight, however you may find yours bent because the DPO screwed down the nylock adjusting nut too much and bent them.

After straightening, put them back together and gently tighten the adjusting nut until the plastic plunger just seals the opening in the cylindrical extension of the TC housing, then tighten it one more turn.

You now need to 'balance' (if you have multiple carbs) and adjust the opening rate of the plastic plunger. This will take some trial and error, but will be worth the trouble. Fill a pan with water, put it on the stove, and place the TC's in the pan so they are completely covered in water and position them so you can observe the opening and closing of the plunger(s) together. Place a cooking thermometer in the water. Turn on the burner real low and observe what temperature the TC's start to open.

Based on much experimentation, I found that the plunger should not start to open until around 115F; at 125F it should be about half open, and at 140F the plunger should be fully open. This will introduce a fair amount of 'bypass' air into the mixing chamber when the ambient temperature is fairly warm (90F plus) - probably having to do with decreased air density as well. These should be taken as rough approximations at best, with probably a good 10F - 15F leeway. My experiments took into account cold starting, warm starting, carb needle adjustments (not being fully lean or rich), and general driveability for both in town and open road conditions.

When you have the TC's in the pan on the stove, keep a close eye on the water temp. If you need to adjust them, and you will, simply take them out of the water, run some cold tap water over them to cool them down, make the adjustment and put them back in the pan. They react very fast. To make the TC's open at a higher temperature, tighten the adjusting nut - about a 1/2 turn at a time.

Most importantly you want the TC's to be balanced, i.e. open and close together at the same temperature.

After they are adjusted, put a drop of Loctite on the exposed threads of the adjusting nut to keep the nut from moving. Don't move the nut, the Loctite will 'seep' down into the nut enough to hold it. Also, check to make sure that the rubber sealing ring in the carburettor body that the nose of the TC's press up against is indeed there and in good shape. Same for the O-ring that goes around the 'snout' of the TC's and presses up against the outside of the carb body. If any of these are missing or cracked you will end up with a major air leak.

Some symptoms I have observed from not having enough bypass air is generally good driveability when cold and poor driveability when warm (if EVERYTHING else is in working order - ignition, timing, compression, etc) . Also overly rich mixture only when warm, difficult warm starting and needle mixture adjustment ineffective only when warm.

I also had the opportunity to test two brand new, unopened NOS TC's that I came across. The two TC's opening/closing characteristics closely approximated my revised findings, however I was surprised (although not very) to observe a 20F - 25F variance in the opening/closing characteristics of these two TC's. Production tolerance?

However, based upon my testing, I believe that the most important operating parameter when dealing with TC's on a multi carb engine is to balance the opening/closing temps and not the absolute temp that the TC's open or close.

Several performance articles I have read said to leave the TC's intact as they are necessary for the correct operation of the carburettors. I believe it, as I tried sealing off the TC's and ended up with driveability and hesitation problems on my TR when it was warm.